index memoir - homepage - contact me at

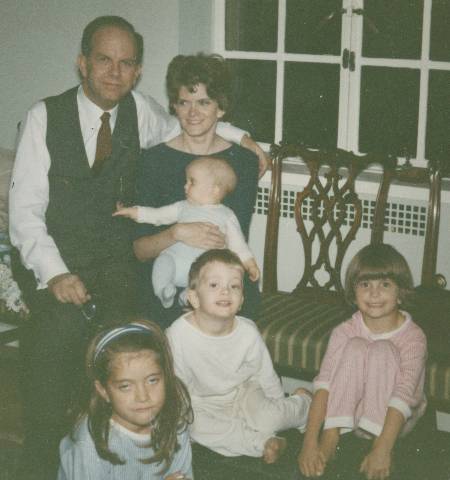

We returned from Pakistan to Copenhagen now with 3 children but still easily fitted into Cubby’s parents large apartment where we stayed most of summer 1964 awaiting reassignment.

|

|

|

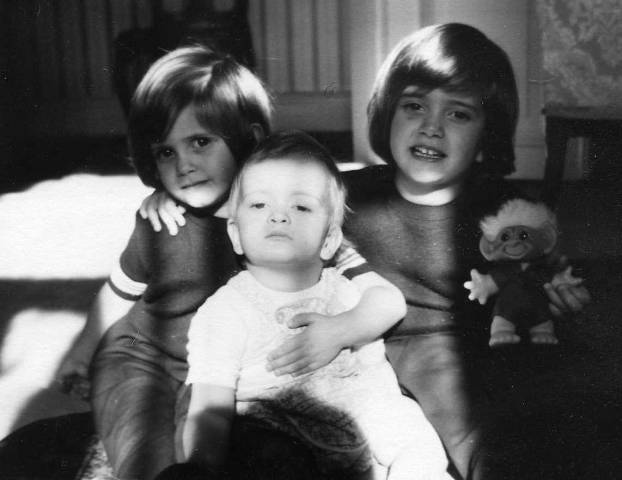

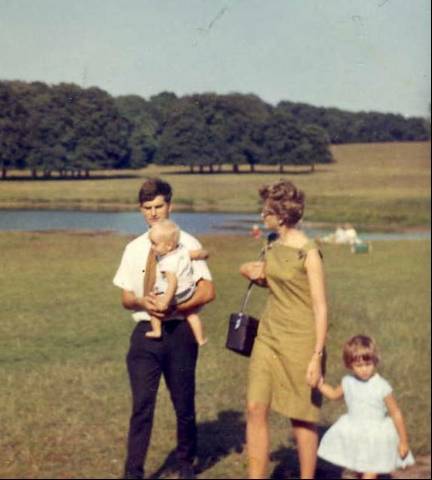

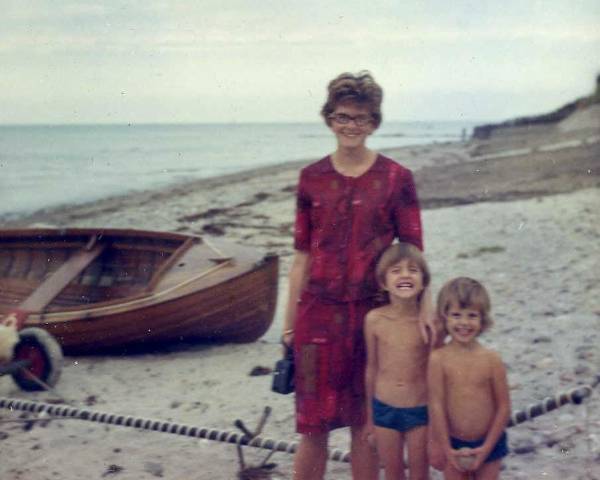

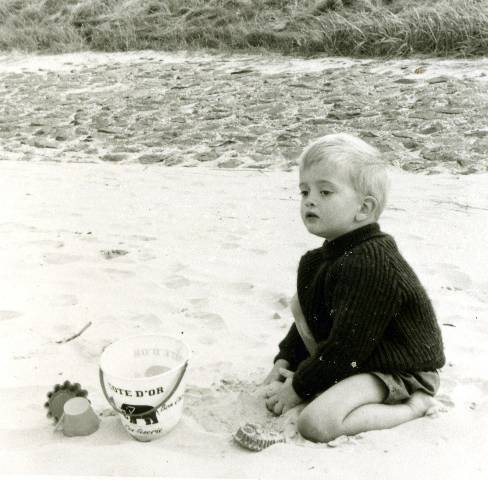

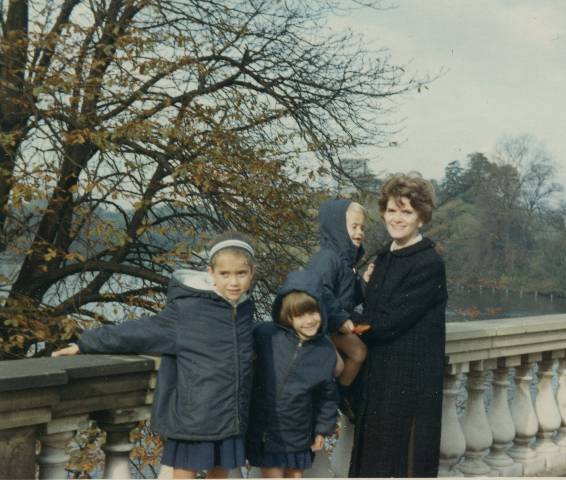

Interlude in Denmark - Karen, Christopher and Nicky settled in Aage's and Mercia's Stockholmsgade apartment. - Walking in Hjortekaer Park - Sampling the cold Baltic seaside |

||

|

|

|

|

1st picture - Karen and Nicky with Farmor (Cubby's grandmother) and Mor Weiss, mother of Soren Weiss (Bodil, Cubby's sister, then husband).- 2nd picture - My twenty seventh birthday party, at back Cubby, Bodil, Mercia, Soren, in front Nicky, me, Karen, Mor Weiss, Farmor.- 3rd picture Cubby outside apartment going for walk. |

||

Some months later I was assigned to Antwerp on the construction of the E3 Schelde Tunnel – a tunnel just upstream of the town of Antwerp in Belgium. In September 64, I joined a small team of Christiani and Nielsen Civil Engineers on site with my family to follow later.

In bilingual Belgium, Antwerp is called Antwerpen in Flemish and Anvers in French. Antwerp is largely Flemish. Although the Belgians had comparatively recently left their wealthy African Colonies - Belgium Congo, Rwanda and Burundi there seemed to be little African influence and customs in this town. Few, if any, Africans were seen and there were no Central African restaurants among the many exotic restaurants we frequented during our stay.

An existing bored tunnel took single lanes of vehicular traffic generally in opposite directions across the Schelde River. Ventilation was poor with a choking haze of blue exhaust fumes. During morning and evening rush hours the lanes were used in one direction only to increase capacity and also to improve ventilation by pushing air in one rather than opposing directions. Cars banked up in holding bays at either end of the tunnel waiting their turn to cross. Staff on the construction of the new tunnel avoided this time consuming journey, they were ferried across the river by a company boat from the right bank, where most lived, to the left bank.

An immersed[1] tunnel rather than a bored tunnel or bridge had been selected for technical[2] and cost reasons to supplement the present inadequate crossing. The immersed tunnel was to be made of sections about 100meters long, each floated out in the river and sunk into a prepared dredged trench on the riverbed and connected together. With an oblong cross sectioned immersed tunnel 47m wide by 10m deep and with 3 internal walls it was possible to accommodate two motorway carriageways with three lanes of traffic in each, two tracks for trains and a cyclist / pedestrian section. The tunnel including portions on the banks built in place was only about 1km in length – not very long - but is still today probably the widest tunnel[3] in the world.

CN had built many immersed tunnels across rivers already in neighbouring Holland and elsewhere. On this turnkey design and construction project they worked within a consortium (Tijdelijke Vereniging E3 ScheldeTunnel) of five companies – four of them being some of the biggest Belgium construction companies.

When I arrived the excavation of a huge ‘dry-dock’ in a dense clayey material was underway on the left bank of the Schelde Rivier. The 5 tunnel elements each (with a future water displacement of 47,000 tons) and also caissons just over 17m high were to be constructed in this dry-dock. After the tunnel elements had been sunk and positioned in the river bed, the caissons were to be floated across the river and sunk on top of one of the tunnel elements reinstating the original stone Quay Wall used by shipping. This quay had been demolished on the right bank to permit the tunnel to pass.

I bought the cheapest available car, a dark blue Czechoslovakian Skoda, and then rented a fairly new two bed-roomed apartment in Wilrijk, a suburb on the outskirts of the town. My Danish ‘boss’ Uffa and his Australian wife, Marion and their two children Karsten and Ellen lived close by. Since our marriage 6 years earlier, this was the first opportunity to equip a home to our own taste and we selected furniture both from Copenhagen and Antwerp. Cubby and the three children joined me in mid October 64. As family planning did not seem to be one of our strengths I had written to Cubby asking her to bring a supply of condoms[4] from Denmark - these were not legally on sale in Belgium - in 1964 it was a staunchly Catholic country.

|

|

|

|

Domestic scenes at Prieel Straat in Wilrijk. Cubby and I expecting guests,Karen reading Nederlands, Mercia, Cubby's mother, visiting and talking to Marion Hansen, an Australian, wife of Uffa Hansen my boss on site. |

||

|

|

Karen in Kindergarden class second from left |

We settled in - our two daughters Nicky 5 years and Karen 3 years were soon being bussed daily to a free government Flemish school with a kindergarten section where they learnt to speak and write Nederlands. School was from 8-30am to 5-00pm for five days a week with Wednesday a half day. Beds provided permitted the younger children to rest in the afternoon if they wished. The Belgian State, unlike Britain at that time, seemed to cater for the needs of families enabling mothers to work if they wished. Our son, baby Christopher, of course stayed at home.

We celebrated St Nicklaas[5] day on the 6th December 94. As was usual in Belgium, we left out a glass of milk for him and his assistant Swarte Piet and a carrot for his donkey – they would be delivering gifts to the children (I am not too sure whether the donkey was also expected to descend the chimneys).

We travelled to Copenhagen by train to spend Christmas in Denmark with Cubby’s family and bought a first set of Lego[6] for Christopher. Back in Antwerp we celebrated New Years Eve 1964, at Uffe and Marions house together with Norwegian engineer Arnvin and his Danish wife Karin. Arnvin was in charge of the construction of Left bank cofferdam and ventilation building and tunnel sections constructed in place.

At the end of January 1965 Sir Winston Churchill died. We saw his funeral cortege escorted by Royal Navy sailors displayed on the screens of television sets in several department stores. Fifty years earlier, during the First World War in 1914 he had rushed in person to organise the defence of Antwerp, which despite this, fell. We had no television set at home considering it to be generally intrusive – instead we listened to BBC radio easily and clearly received.

In the earlier stages of the project, while planning construction methods in the office, I was worried by my lack of French which seemed to be the only language many of the suppliers of construction equipment and materials spoke although most of the consortium’s engineers and senior foremen spoke good English, I started taking French language lessons in the evenings after work, but did not persist – when work started on the site itself I found that most of the foremen and workmen were Flemish. The Flemish language is essentially the same as Nederlands, but the accent is somewhat different – a regional dialect. My basic knowledge of Afrikaans, learnt at school in South Africa, was sufficient to make me reasonably fluent in Nederlands within a few months and able to communicate directly with the workmen without relying on interpreters

|

|

|

|

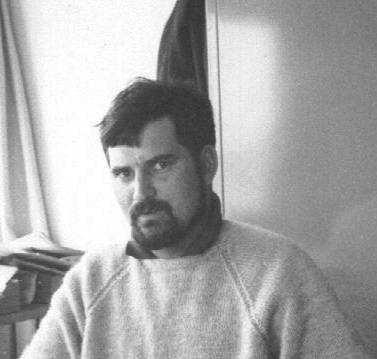

Civil Engineers from Christiani and Nielsen - 1st pict.- me, in charge of concrete and formwork for tunnel elements and caissons - 2nd pict. - Erling Bjorn Pietersen, in charge of rebar and post tensioning - 3rd pict. - Arnvin Johannesen in charge of construction right and left bank cofferdams and Left bank insitu tunnel and ventilation building - 4th pict.- Uffa Bondeberg Hansen Manager in overall charge of left bank works |

|||

I was responsible for the concrete and formwork for all the precast concrete tunnel elements. Another CN engineer Erling Petersen was in charge of the rebar and post tensioning. The top and bottom slabs of the elements were post tensioned - 50m long prefabricated ducts and cables were carried and placed across the tunnel slabs on supports at various levels by a crocodile of men supervised by a Spanish foreman Martinez - rebar was then completed the slabs concreted. Stressing with huge jacks followed some weeks after the 1,2m wide double construction joints[7] splitting up the slabs had been concreted.

Specialist Belgian surveyors did the setting out - we were not burdened with this chore usually undertaken in England at that time by young engineers. The Client had only one inspector in the dry dock checking the rebar. We as contractors were totally responsible for the quality and execution of the works. There were no Resident Engineers on site (as was the usual practise in British contracts at the time), no conflict and no tedious contractual correspondence.

Although we had a minimum of written procedures and formal inspections (as later became obligatory in the construction industry starting initially in Nuclear Power plants), we planned and executed our work to a high standard. We had experienced foremen (lead by multi-lingual Jean le Ferve who spoke four languages) and a skilled willing labour force provided by our Belgian partners. There did not seem to be any trade union strife and conflict with management as I was later to experience in England.

The labour travelled in weekly on Monday mornings from all parts of the country – staying in temporary accommodation in Antwerp and returning home on Friday afternoons – effectively a short 5 day week was worked. The lack of Saturday and Sunday work, as commonly done in England at the time, supposedly for production but more usually to top up staff and labour wages, did not seem to affect production – rather the opposite – fresh rested labour gave better output. The main concession made to this short week was that all concreting was done at night. Large gantry cranes straddling the elements placed concrete with 2 cubic metre buckets. Placing concrete with mobile pumps with hydraulic booms had not yet been introduced in Europe. This night shift concreting ensured that the same handling plant could be used uninterrupted on formwork and rebar in daylight hours.

Solid meals, soup seemed obligatory in Belgium, were provided at lunchtime. We would drink some light Belgian beer (which today probably would not be acceptable from a safety aspect). Even worse on rare freezing iced up mornings, the Chief Foreman offered the Engineers a small glass of Geneveer (Dutch Gin) to warm them up before going outside.

| |

Cross section of temporary dry dock on the left bank showing two rows of tunnel elements with gantries over each row and a tower crane between the two rows. The bachplant supplying the concrete is at ground level and an inclined lift conveyed concrete to dumpers at the floor of the dry dock |

|

|

Tunnel elements and right bank quay replacement caissons shown in dry dock . |

The concrete for the tunnel elements was batched and mixed on site rather than using ready mixed concrete from outside plants. Barges conveyed rounded stone dredged river aggregates (rather than crushed stone) and sand to the site where they were unloaded by grab crawler cranes into hoppers on the left bank cofferdam and delivered by conveyors to stockpiles above a reclaiming tunnel before the batchplant. Blast furnace slag, a by-product of the steel industry, was commonly used in cement in Belgium at the time. We used a cement made from Portland slag and blast furnace slag which gave a low heat development with less potential cracking, and relatively impervious concrete compared to a 100% Portland cement. The use of fly ash in concrete as a pozzolanic material, giving similar results, only began to be used much later in Britain – probably as there was no financial advantage to cement suppliers.

As the tunnel elements would be floated out and ballasted with water in tanks to sink them and also with stone to keep them permanently safely on the bottom, it was important to estimate accurately the actual weight of each completed tunnel element. Concrete unit weights were measured first in trial mixes and later on site as a ongoing control. The water demand per cubic metre of concrete to achieve workability (flow and compaction when placing and vibrating the concrete) was low. Rounded aggregates caused less friction than crushed aggregates and an admixture also further reduced water required. Some further water was squeezed out by the concrete weight itself and by vibration - again making the concrete heavier.

Normal aggregate Concrete acts largely as a heavy liquid and generally weighs about 2.4 tons per cubic metre compared to water weighing 1 ton. Fluid concrete pressures were later found to be up to 9 tons per square meter when it was vibrated in walls (measured in site trials with pressure meters at various heights). We had anticipated that pressures would only be about 6 tons per square metre. Fortunately the steel panelled formwork (with thin steel facing plates) and ties were sufficiently strong to resist these greater pressures although some minor deflection rippling on the cast faces was apparent. Cores later bored from walls and slabs at various levels reflected the greater unit weights with placement pressures.

As we did not want the elements to weigh more than estimated by the designers originally we deliberately set all wall forms ½ cm tight and made floor and slab thickness 1cm thinner to allow for over thickness which generally occurs during concrete placement.

In the end these elements floated in the drydock. Only 5cm of the 10m deep elements showed above water – 0.5% - not much margin – the elements were a little heavier than had been foreseen and indeed had to be ‘unstuck’ from the dry dock floor by jetting in air to break the vacuum effect before they would float.

|

|

|

|

Batch plant with children and our blue Skoda parked in front. - Slip forming Right Bank quay replacement caissons - inspecting one of first tunnel bases after casting: me, Jan Lefevre our Belgian Conducteur de Travaux (fluent in 4 languages), and the Manager for all Left Bank Works, a Dane, Uffa Bondeberg Hansen |

||

We had asked for quotations for formwork design and supply for the tunnel elements from several European companies, who came up with their own concepts. Acrow the English company (motto – Grow with Acrow) had a good local agent, Mr Bayet of P M Cassart. They were prepared to fabricate the steel sections (required behind the Acrow standard panels and on top of scaffolding frames), on the site and easily undercut the price of their competitors. Acrow seemed to be a very successful company internationally for many years afterwards then inexplicably became bankrupt leaving the field open to their competitors.

We met Oliver and Jean, friends from our Cape Town University days, now living in Den Haag with their young children. The was the same Oliver, now working for an oil company, who had carelessly had his rifle stolen from the train on the way to Citizen Force army camp in South Africa. We walked around the ‘red light’ district in Den Haag looking at the girls displayed in their windows – some appeared annoyed that our wives accompanied us. Oliver and family in turn visited us in Wilrijk - Oliver falling asleep and snoring at the table after a heavy meal and much red wine.

|

|

|

Cubby and Margriet with children in woods near Antwerp |

|

Neville and Margriet also from Cape Town University were in Antwerp. Neville, an accountant, was working for an international trading company. He had gone to the same high school, Rondebosch, as I had and still loyally sported an Old Boys tie - unrecognisable to most Europeans. I had taken blue eyed, fresh complexioned, pretty Margriet, whose parents had migrated from Holland to South Africa, out a few times at University to parties before meeting Cubby.

I played tennis with Neville and some American friends mainly on indoor gravel courts not subject to the gloomy vagaries of Belgian weather. The Americans worked for their Consular service. They seemed to think that European nations should also become involved in the Vietnam war against a communist threat which they considered was then escalating - if South Vietnam fell to communism other Asian nations, like a string of dominoes, would fall. Fortunately the European countries remained lukewarm about this conflict considering it none of their business. Neville read Playboy for its intellectual rather than pictorial content according to his wife Margriet, and I less ambiguously borrowed the copies to look at the foldouts.

Antwerp had many restaurants, nightclubs and strip joints incongruously clustered around the ancient cathedral where we dined and saw shows – none of which appeared very pornographic and were watched mainly by dining staid middle aged married couples. Restaurant food was generally plentiful and good even if too much butter and cream was used than recommended by the health conscious nowadays. We sampled our first Indonesian style cuisine[8] – spicy condiments, such as blatjang, made of rotting shrimps and chillies, took some getting used to.

|

|

|

Chilly beaches in Holland - Nicky and Christopher |

|

Over relaxing weekends with no Saturday site construction work, we visited many neighbouring Dutch towns and seaside resorts especially the Beveland peninsula between Oster and Wester Schelde with white sands, chilly water and the occasional sunbeams. This peninsula was not yet linked to the other sides by huge precast concrete bridges (built many years later), so we enjoyed crossing the watery gap by car ferry. Children always seemed welcome in Belgian and Dutch restaurants and probably because of this behaved themselves – in England at that time in many areas it was difficult to find a restaurant let alone one welcoming children. Wayside snacks - Belgian frites (twice deep fried) and waffles with lashings of cream were enjoyed. Delicious Belgian beer and chocolates with real cream were guzzled. I put on weight.

A business meal given by our batch plant supplier on award of the contract lasted almost 8 hours – the offer afterwards for entertainment by young ladies of the town was declined.

Nicky often suffered from tonsillitis ‘cured’ by antibiotics, but as it frequently re-occurred we had them ‘out’- effectively they were only cut off. Photographs after her recovery show her with skinny legs riding a bicycle outside the apartment on the pavement.

|

|

|

Visitors from Denmark - 1st Pict. - Cubby's sister Bodil with her husband Soren Weiss and Karen and Nicky in Brussels Grande Place - 2nd pict. - Aage, Mercia and Bodil (Soren taking picture) dining with Nicky and Karen - 3rd pict. - Christmas 1966, Karen gets the almond in her rice pudding and receives a prize, while Mercia is in a celebratory mood. |

||

Early in summer 1965 Cubby’s parents and her sister Bodil and her husband Soren Weiss the actor drove down and visited us. They stayed in a small garishly decorated hotel near us, probably truthfully nicknamed by us ‘the bordello’. This was a good excuse to travel to Brussels to see the Grande Place and Manikan Pis.

We decided to go camping on the Cote Azur in the South of France for our first summer holidays in July 1965 – the whole Belgian construction industry conveniently closed down at the same time. Learning from our earlier rough camping trip to France taken when based in Yorkshire, we bought a large tent supported by an internal jointed metal frame. An inner hanging cloth enclosure formed two zip-up rooms and beside them was a large covered open area. It was sufficiently large for three children and us. We trial pitched the tent taking 2 hours – later this reduced to ¼hour during the holiday.

We avoided travelling in these summer months down the direct route through France used by the thousands of holidaymakers from all parts of Western Europe – travel by Eastern Europeans from communist countries was not possible. We instead drove, through the Ardennes then through Switzerland camping overnight. The stretch from Lausanne to Geneva was on a remarkably smooth concrete road, one could scarcely feel any bumps between cast sections – how has this road worn over the past 35years? With heavily laden roof rack we struggled through mountain passes to Grenoble, Digne on to Frejus, on to our campsite near Colombier two miles from the sea. That night the moon rose like an orange ball in the purple sky above the black pines around our tent.

Nicky after some hesitation found that she could still swim, Karen and Chippy frolicked in the water. The beaches still had space - not yet packed with diverting bronzed topless women’s bodies as in future years. We rested, lay in the sun, ate ripening slightly ammonia smelling Camembert spread lavishly on baguettes, munched succulent peaches, figs and melons. We cooked fresh courgettes, aubergines and tomatoes in olive oil. Flavoured this with garlic and Provencial herbs - ate it with saucisson and spaghetti sprinkled with grated cheese - all washed down with copious quantities of red wine.

We returned to Belgium by the more direct route via Aix en Provence, Avignon, Lyon and Dijon where we camped overnight before reaching Antwerp. I returned to work now gathering momentum on the construction of the tunnel elements. A problem had occurred on the project – sheet piles in the right bank double wall cofferdam had deformed more than expected when filling soil between them. A decision was taken to drive a third sheet pile wall of heavier piles fortunately not delaying the project.

The children still had 6 weeks of their holiday to pass, and Christopher celebrated his 2nd birthday. With three children for Cubby to look after and being more affluent we took on a maid who came in one day a week. She, Mary, was a Belgian who had spent much of the war years in Britain and spoke English – this gave Cubby the chance to go into town without children in tow.

In September 1965 a pageant was held marking the 1,200year birthday of our modern suburb Wilrijk which strangely being so ancient did not seem to have any old buildings. People dressed in the style of Bruegal and Hieronimous Bosch - gap toothed and pock marked – wandered through the streets.

Cubby was again pregnant – our apartment would be too small with four children - we had to find a bigger one, but could not do so until we found replacement tenants to take up the lease on our existing one.

|

|

|

|

1st pict. - Dorte with father Aage 2nd pict. - Dorte and Ole Eisen - 3rd pict. - Ole and Dorte with his mother, mor Rita - 4th pict. - Dorte and Ole with his sister Karin and her husband Erling Heerwagen, talented ceramists at Lohals on Langeland Island |

|||

Cubby’s sister Dorte married Ole Eisen in November 1965 in Copenhagen, but we burdened with children and with one on the way we couldn’t attend the festivities.

We spent a quiet Christmas 1965 at home, but before this Cubby’s parents spent St Nicklaas celebrations with us.

|

|

|

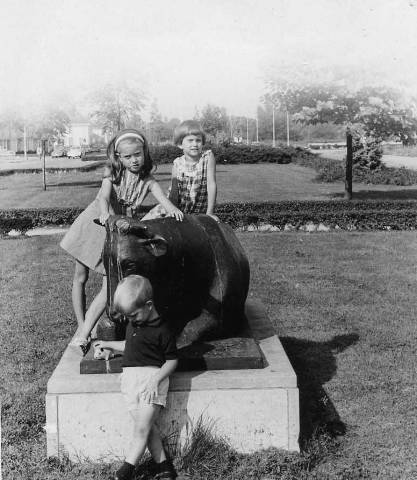

New apartment at Groenenborgerlaan - children with cow statue - Aage outside apartment - family in window - Ole and Dorte in middle with Bodil on right |

||

After some apartment prospects fell through, we found in January 66 both replacement tenants and a large new apartment close by and moved. From our window on the 2nd floor we had a view of a large bronze reclining cow chewing the cud in the island between the two roads. As no apartments were across the street looking in at us, we did not provide net curtains – our apartment managers commented on this as our windows did not conform with neighbour’s floors above and below.

The project survived a potential natural disaster. An unusual combination of high spring tides combined with strong continuous winds in the North Sea which raised the water level in the Schelde River to very high levels that could have overtopped both the left and right bank cofferdams causing serious flooding and delay to the works. Sandbags were filled and placed behind and above the sheet piles. The Project Manager Mr Beyers crossed the river and anxiously watched the rising water and unlike King Canute was relieved when it stopped only 15cm below the sheet piles – disaster had been averted

|

|

|

New arrival Andrea with Cubby, Nicky and when somewhat older in bouncy chair with Karen |

||

Cubby was pre booked into nearby St Augustine’s Clinic run by nuns for the birth. With contractions starting in the early morning, Cubby still found time to repair Karen’s anorak zip before going to the hospital at 6-30am on 19th April 1966. I returned home to dress and breakfast the children before dropping them all off at neighbour Marion and returning back to the hospital – this would be the first and only birth I would see. After waiting some hours, Cubby appeared to be ready to deliver but was not pushing sufficiently. A young nurse then gave a hand by climbing on the bed pushing her feet against the bed head wall and simultaneously pushing Cubby’s stomach (rather like a rugby scrummager) – out popped Andrea weighing 3kg 200grms looking much like her sisters. Cubby was all for going home immediately, but the Belgian doctor ordered a weeks rest at the Clinic before she returned home.

About 3 weeks after Andrea’s birth Karen had her tonsils out, the operation and recovery being so quick that Cubby could get home in time to give Andrea her next feed. Cubby’s parents Aage and Mercia came to see their new grandchild Andrea, bearing much appreciated gifts of clothes not only for her but for the older children also.

Concrete production on the tunnel elements reached a peak of10.000, cubic meters of concrete in June 1966 and then declined in subsequent months.

|

|

|

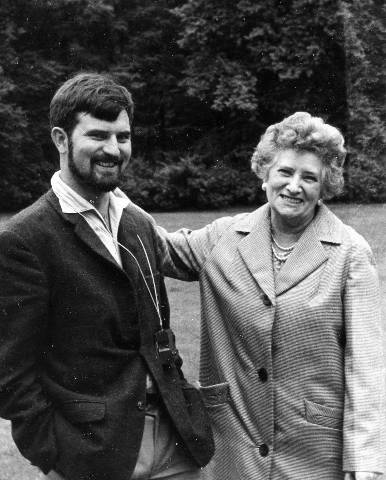

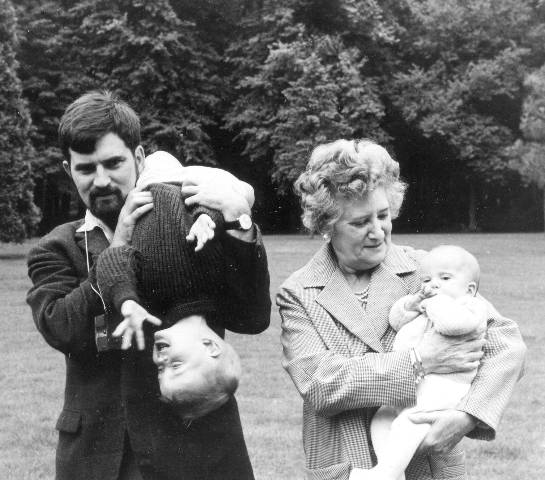

My mother with me - me, Christopher, my mother and Andrea - Nicky, Karen, my mother and Christopher |

||

My mother Bonnie, a sprightly 59 years, flew over[9] from Cape Town leaving my father at home and stayed with us at the start of the 1966 summer holidays. This was the first time she had seen us since our departure from Cape Town in 1959 and her new grandchildren. Leaving Cubby and the two youngest children at home in Antwerp, my mother and I and Nicky and Karen drove to Amsterdam, an orderly neat city with canals, stepped gabled[10] houses and many bicycles. Amsterdam had at this time no reputation for relaxed acceptance of drugs and seemed a prim and proper town – no hippies about. We visited the Museum of modern art and viewed many of van Gogh’s paintings including the coarse potato eaters, drank good Dutch coffee and stayed overnight. My mother departed for coach trips in Britain before returning to South Africa.

Andrea thrived but one evening cried persistently after being put in her cot then stopped presumably having fallen asleep. For some reason I was uneasy and went into her room. I found that the ribbons tying her jump suit behind had become entangled with a cot wing nut while she was standing up. She was in effect hanging from this nut with her garment tightening around her neck. Fortunately she had not lost consciousness and recovered directly.

Karen when suffering from some childhood complaint was prescribed a new antibiotic. We were alarmed to read in one of the English Sunday newspapers that this particular antibiotic could produce side effects. Indeed although she recovered she was continually unnaturally tired. A check showed that the antibiotic had made her anaemic and a course of iron followed which seemed to solve the problem.

|

|

|

Visit to London - In Aage and Mercias apartment near Hyde Park. - Cubby and children at the Serpentine. |

|

In October 1966 we took a ferry from Ostend to Dover and drove to London in our Belgium number plated Skoda visiting Cubby’s parents in their apartment overlooking Hyde Park. Cubby’s father, who had been transferred from Copenhagen to London as CN’s Manager, was just recovering from a ‘slipped’ disc making his settling in at home and at CN office rather difficult. We were pleasantly surprised how easy it was to drive in London despite our steering wheel being on the wrong side – English drivers were very polite giving way to one if they saw one hesitating, particularly if one had a red numbered foreign plated car. The traffic seemed to flow quite freely on Park Lane in contrast to the traffic jams we found 30 years later.

The walls of the five quay re-instatement caissons 17,5m high were constructed one after another starting in September 66 and were completed in February 1967. On each caisson sliding forms were progressively jacked up round the clock on tubes (spaced within the walls) extended as the work proceeded. The concrete rose about 150 to 250mm each hour, sufficiently slowly so that it had set when the 1,2m deep forms slid past 5 to 6 hours later. With the setting and hydration of the cement in the concrete it became very warm inside the cells. Placing horizontal rebar in the limited space under the yokes at jack points set the rate of progress rather than concrete placement and vibration.

The construction and fitting out of the tunnel elements in the dry dock proceeded with the placement of temporary bulkheads, rubber (Gina) seals, and ballast tanks. A specialist engineer with previous experience in floating and sinking tunnel elements came to site to sink the elements. We after an enjoyable stay in Antwerp prepared to move to CN head office in Copenhagen missing the sinking.

As accommodation was difficult to find in Copenhagen, Cubby had gone on a short reconnoitring trip accompanied by the two youngest children. It was nerve racking boarding the train with Andrea in a carry cot during a stop of only minutes at Antwerp, and then the hassle with two children in tow down the corridors to find the reserved compartment. In Copenhagen she her sister Dorte, who now also proudly had baby Tim who was one year younger than Andrea, put her up.

Shortly before our departure friends Susan and John visited us from London and after dining we visited one of many nightclubs in town where we were entertained by a very attractive exotic dancer who ended her performance by sitting on my lap. I blushed even more when she removed her wig and revealed herself as being clearly male – John sometimes reminds me of this and I grin shamefacedly.

Before leaving Antwerp we enjoyed some celebratory white tablecloth meals with many courses given by the company on restaurant boats plying on the Schelde. We later heard that the sinking of the elements had gone according to plan. One unforeseen event occurred – the river came down in flood with much silt increasing its density and the uplift on elements - water ballast within the tunnel elements had to be increased directly to prevent a tendency to re-float.

|

|

Picture of family taken by Jenny Lawrence just before leaving Antwerp |

[1] CN built the first immersed tunnel in 1938 across the Maas River in Rotterdam

[2] Several bored tunnels would have been required for the same traffic volume, and would have had to be both deeper and longer

[3] The Encyclopaedia Britannica confirms this

[4] The contraceptive pill became available in Britain in 1962

[5] In America the name St Nicklaas, introduced from Europe, was transformed into Santa Claus.

[6] Lego was now in the present form of the plastic interlocking building bricks but originally the company had made rather superb Wooden blocks and other toys.

[7] These joints was to enable construction in manageable sizes and as a means of controlling the amount of shrinkage cracks in concrete

[8] We were later to sample real Indonesian food 20 years later when we worked and toured in Sumatra and Java.

[9] About 40 years earlier my mother about 20 years old had visited London with her parents and she recalled how much it had changed – thin pinched looking children no longer grovelled and snatched cigarette butts from the ground when discarded by smokers.

[10] Stepped compared to the curved gable Cape Dutch gables in South Africa.

index memoir - homepage - contact me at